For industrial manufacturing applications, the rubber dip molding process offers flexibility and customization. Dip molded rubber products are created using molds called mandrels. Read More…

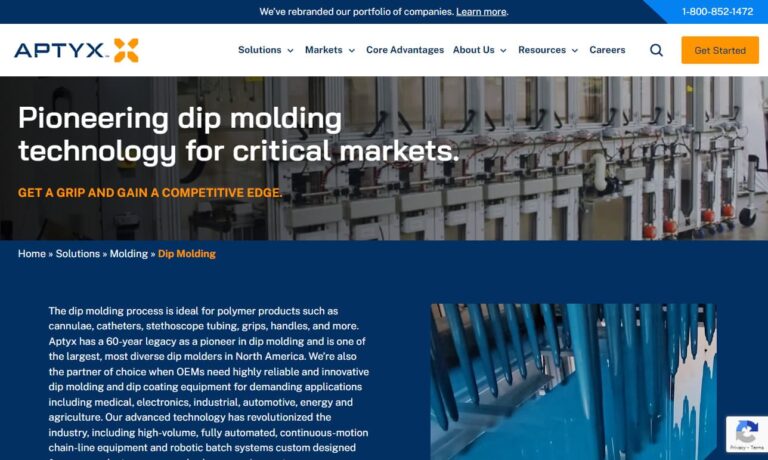

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

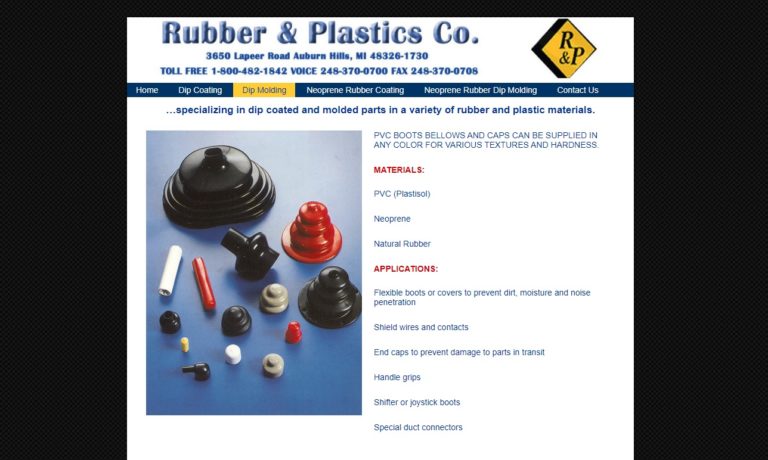

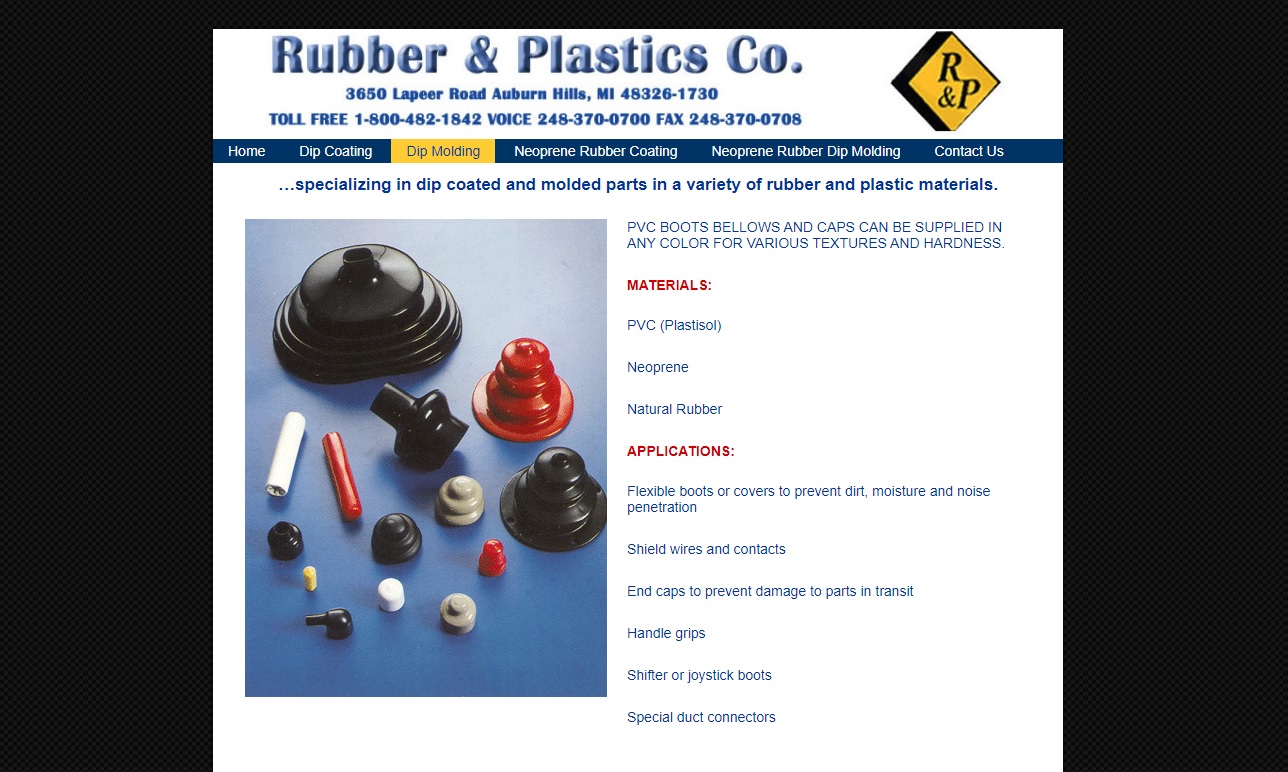

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Rubber Dip Molding Companies

Dip molders often use generic mandrels to manufacture simpler rubber products like gloves and grips. However, manufacturers can create customized mandrels to mold more unique or specialized products. Once the mandrel has been created, it is dipped in a liquid rubber bath.

The number of dips and the dipping duration can all be altered to achieve different molding properties. The more rubber dips are applied, for example, allows for the creation of a much thicker rubber layer, and a similar result can be achieved by dipping the mandrel for a longer duration.

Dip molding can be used to create products for many different applications and industries. Electronics, medical, automotive, and manufacturing companies all utilize dip molded rubber products extensively. For example, dust boots and bellows are common rubber dip molded products. Creating rubber products this way offers several advantages. Rubber dip molding is a cost-effective solution for rubber manufacturing as these products typically utilize a pre-existing mandrel which lowers tooling costs.

Customized mandrels are substantially less expensive than injection molds and manufacturers usually store these mandrels for future use. Additionally, this process allows manufacturers to create multi-layered products. After the initial dipping, the product can be dipped several more times to create additional layers and coatings. Cost-effective flexibility and customizability make rubber dip molding an excellent option for quick and efficient rubber manufacturing.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services