Plastic end caps are a type of plastic component that are used to cover or protect the end of a tube or rod. They can be found in a wide variety of industries, including automotive, construction, and manufacturing. Read More…

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

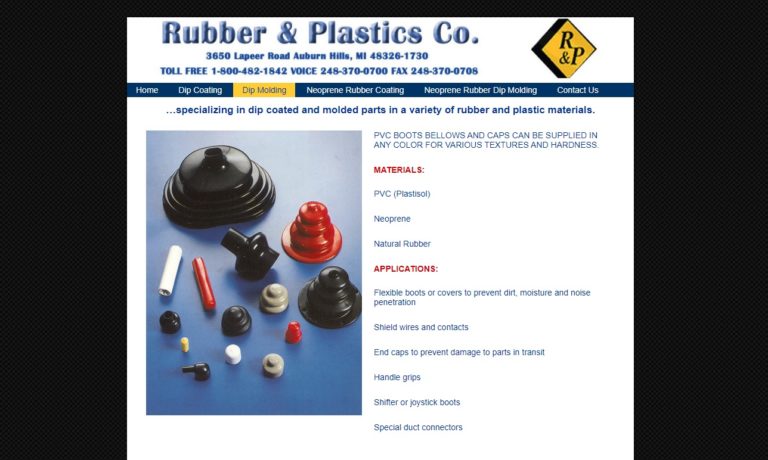

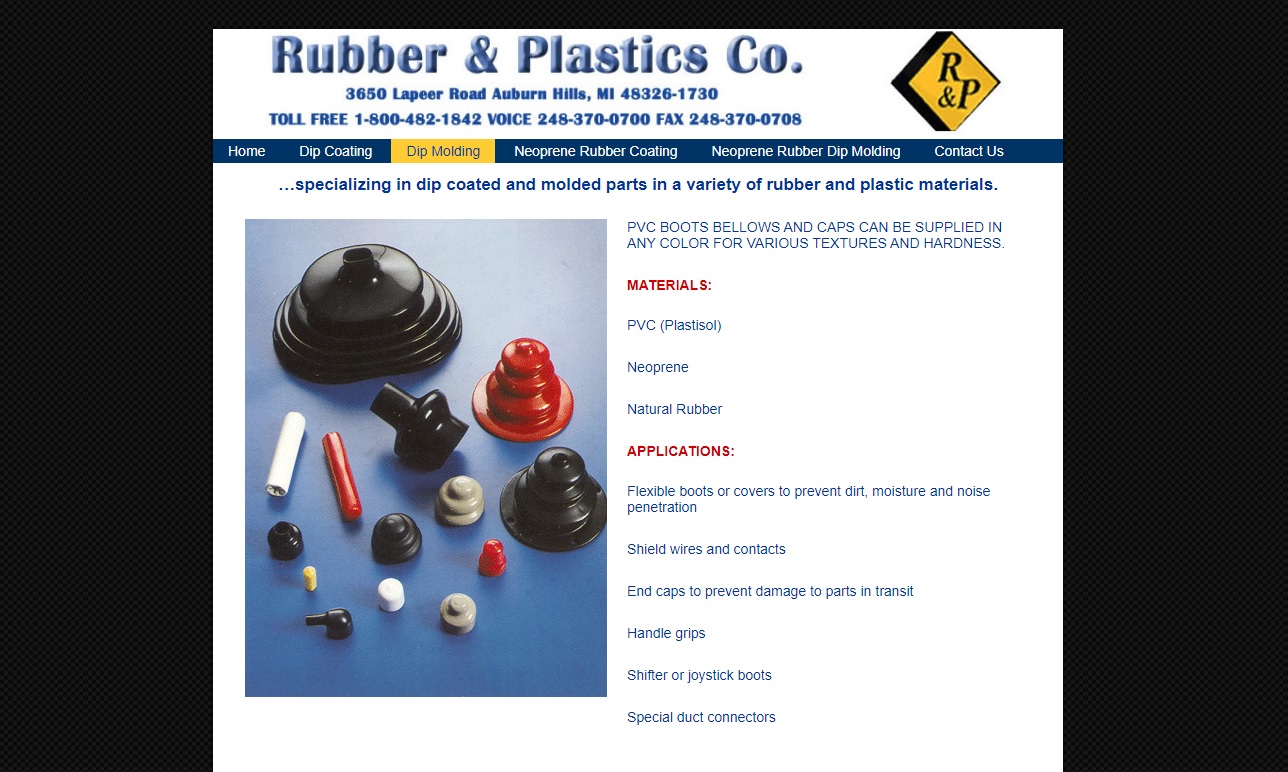

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic End Cap Companies

Producing Plastic End Caps

Plastic end caps are typically formed through the dip molding process. In this process, a mold is dipped into a vat of molten plastic, and then pulled out and cooled, creating a thin, flexible layer of plastic around the mold. The mold is then removed, leaving behind a hollow plastic end cap.

The dip molding process is favored for producing plastic end caps because it allows for the creation of customized shapes and sizes with ease. Additionally, dip molding is a cost-effective and environmentally-friendly way to produce plastic end caps.

Alternative Production Methods for Plastic End Caps

Injection molding, blow molding, and thermoforming are other processes that can be used to create plastic end caps. Injection molding involves injecting molten plastic into a mold, which is then cooled and removed to create a solid plastic end cap. This process is used to create complex shapes with high precision and is often used in the production of large quantities of parts. A specific application for injection molding in creating plastic end caps is in the manufacturing of medical devices. Injection molding allows for the production of custom end caps that are designed to fit specific devices, ensuring a tight seal and protecting against contamination.

Blow molding, on the other hand, is a process that involves inflating molten plastic into a hollow mold. Once the plastic cools and hardens, the mold is removed, leaving behind a hollow plastic end cap. This process is ideal for producing large quantities of uniform parts with a consistent wall thickness. One specific application for blow molding in creating plastic end caps is in the production of containers for liquids, such as shampoo or cleaning products.

Thermoforming is a process that involves heating a sheet of plastic until it is pliable and then molding it into shape. Once the plastic cools and hardens, the mold is removed, leaving behind a solid plastic end cap. This process is ideal for creating large, shallow parts with simple shapes. One specific application for thermoforming in creating plastic end caps is in the production of protective covers for electronics or machinery.

Considerations Regarding Plastic End Caps

The creation and use of plastic end caps also come with considerations to account for. One of the main concerns is their impact on the environment. Plastic end caps, like all plastic products, can take hundreds of years to decompose and can cause harm to wildlife if not disposed of properly. Manufacturers of plastic end caps have taken steps to address these concerns, including using biodegradable materials and designing end caps that can be easily recycled.

Benefits of Plastic End Caps

Plastic end caps offer several benefits that make them a popular choice in various industries. One significant advantage is their ability to provide protection against damage, contamination, and debris for the object they are covering. For example, plastic end caps can protect threads on bolts or keep the end of a tube or pipe free from debris or moisture during transportation. Additionally, plastic end caps help to prolong the lifespan of the object they are covering by preventing wear and tear. Another benefit of plastic end caps is their ability to be customized with branding or labeling, making them a valuable marketing tool for businesses. Companies can add their logo or contact information to the plastic end caps, which helps to increase brand recognition and promote their business.

Plastic end caps also offer a cost-effective solution for businesses. They can be produced in large quantities at a low cost, which makes them an attractive option for businesses looking to reduce their manufacturing expenses. In addition, they are lightweight and easy to install, making them an ideal solution for companies looking for a quick and easy solution to protect or cover their products. Furthermore, plastic end caps are also resistant to chemicals and can withstand extreme temperatures, which makes them a suitable choice for use in various industries.

Applications of Plastic End Caps

Plastic end caps have numerous applications in various industries. In the automotive industry, for example, plastic end caps are used to protect the ends of pipes and tubes, such as brake lines and fuel lines, from damage and contamination. In the furniture industry, meanwhile, plastic end caps are used to cover the sharp edges of metal chair legs or table legs, preventing scratches and damage to floors. Additionally, in the construction industry, plastic end caps are used to cover exposed ends of pipes or rebar to protect workers from injury and prevent corrosion. In the manufacturing industry, meanwhile, plastic end caps are used to protect delicate or expensive machinery during transportation or storage. They are also used to protect the ends of tools or equipment during manufacturing processes, ensuring the finished product is free from damage or contamination.

Another application of plastic end caps is in the medical industry. There, plastic end caps are used to protect the tips of medical instruments during transportation and storage. They also help to prevent contamination and protect against damage, ensuring the instruments remain sterile and in good condition. Plastic end caps are also used in the consumer goods industry where they are used to protect products during shipping and storage. There, they are also used to enhance the appearance of the product by covering unsightly ends or edges.

Choosing the Right Plastic End Cap Supplier

To ensure you have the most productive outcome when purchasing plastic end caps from a plastic end cap supplier, it is important to compare each company using our directory of plastic end cap suppliers. Each plastic end cap supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each plastic end cap business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic end cap companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services