Plastic plugs can be formed in different ways such as injection form molding, or blow molding, but one of the most common methods of manufacturing plastic plugs is through the process of dip molding. Plastic dip molders form a mold or mandrel in a hollow version of the shape they desire. Read More…

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

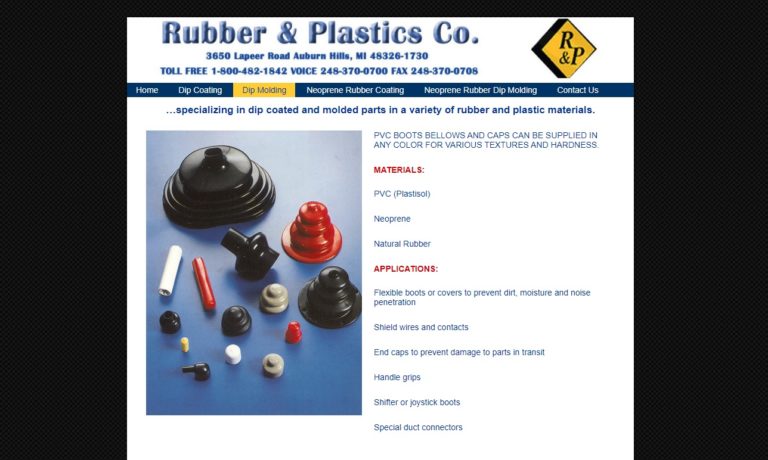

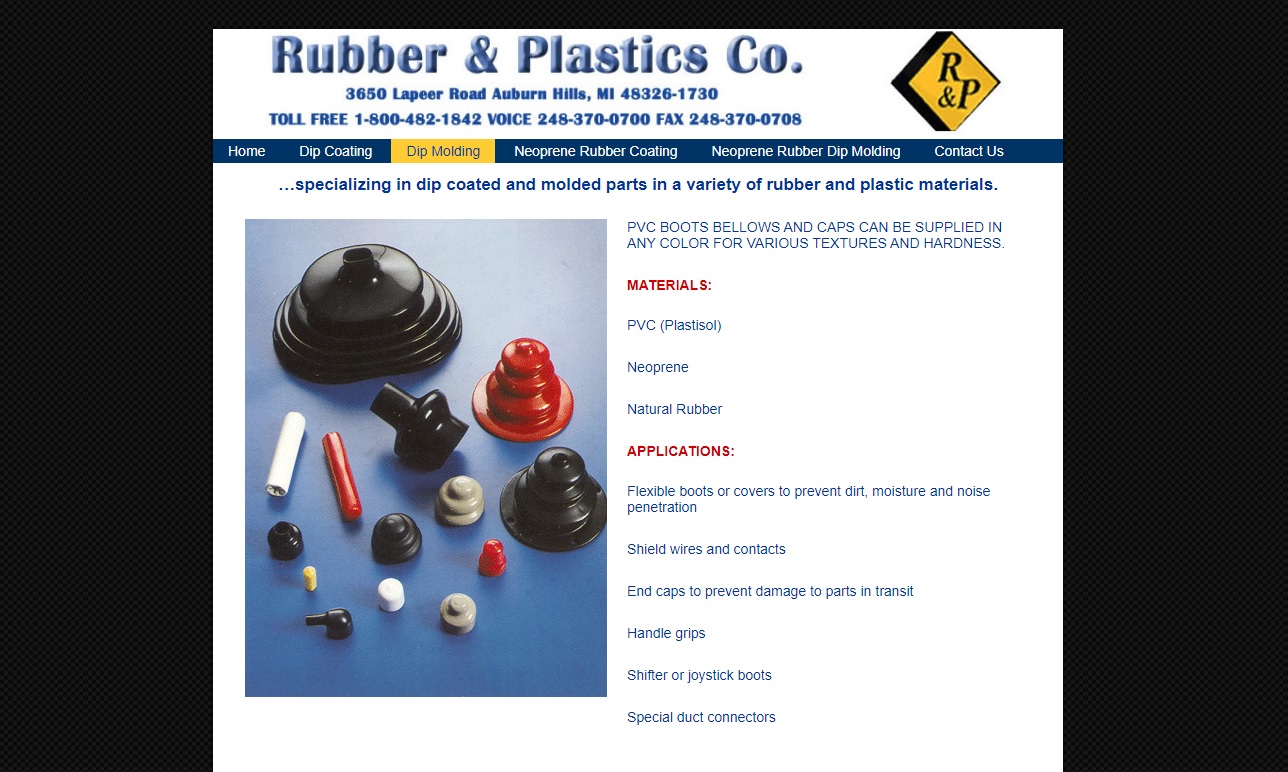

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic Plug Companies

This mold is then dipped into a container of molten polymer, usually a material such as PVC pr plastisol which has been heated to its ideal viscosity. Once the mold has reached its desired dwell time in the plastic, it is slowly removed and the plastic coating is left to harden. Depending on the polymer used, the covered mold can be heat treated to further achieve the desired finish. Used by industries such as automotive, finishing, food services and HVAC, plastic plugs and plastic caps are a common stock item and as tubes, pipes and fittings often come in standard sizes, it is possible to source plugs to fit those sizes from warehouse suppliers.

Common types of plugs include round, square or rectangular, but they can be manufactured in custom shapes too. By adjusting liquid temperature, dip speeds and times and withdraw speeds, manufacturers can design plugs with varying color, texture, wall thickness, material hardness and length. Tapered plugs can fit into a number of openings and still provide a satisfactory seal. As plugs are often used to provide seals, it is important that they fit correctly, especially in the case of a waterproof or airtight seal and so high precision is required.

Plugs can be molded to be flush fit when they are used to fill a hole in a piece of metal sheeting or a hole in the side of an automobile under construction for which a smooth surface is required. Other plugs that are used on a temporary basis can be constructed with pull tabs for easy removal. Square plugs click into place, and grooved plugs grip tightly to the interior of the opening ensuring a secure fit.

For each of these plugs, automated machines can perform most of the dip molding process, allowing labor costs to be relatively low. Each plastic plug takes only a few minutes to manufacture from start to finish, and dip molded objects rarely require secondary finishing. Therefore, high quantities of plugs are able to be produced in fast turnaround times.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services