Rubber & Plastics Company

Rubber & Plastics CompanyRequest A Quote

Auburn Hills, MI | 800-482-1842https://www.rubberandplastics.com/dip-molding/

Rubber & Plastic Company has the proven track record and years of experience you can trust for any plastic and rubber dip molding or coating need. We handle all of our processing on-site in our 25,000+ square feet of facilities. We mention this so you know that all of our products are of the highest quality because our reputation depends on us continually supplying high quality products like we have been for the last 50+ years. We value quality and customer service above anything else in this industry, because we know those two things are the backbone for any successful business.

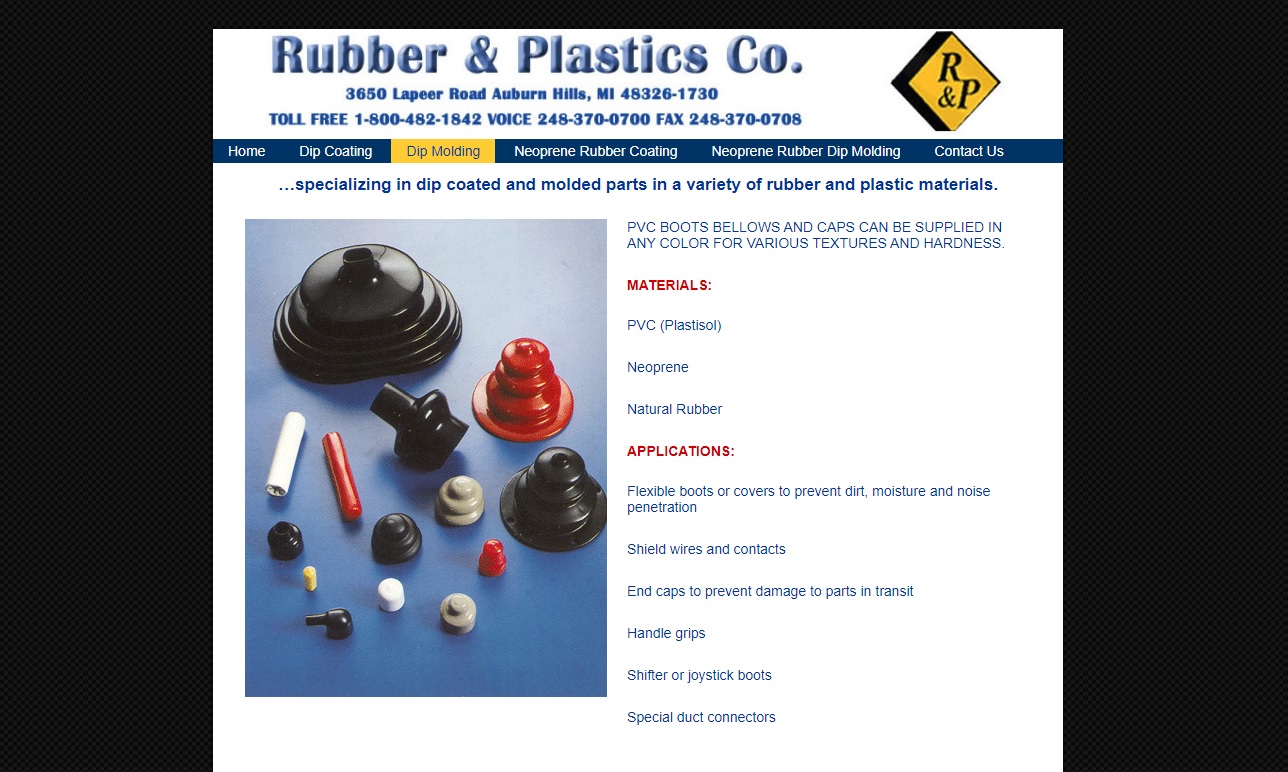

At Rubber & Plastics Co. quality is more than a concept, it’s our pledge to a way of doing business. We’re proud to say that all of our systems meet the approval of government, automotive and other industry standards. We offer a variety of materials for our dip molding products, from PVC, Neoprene, and Natural rubber you can be sure that we use only the best materials for all of our products. Our dip molded products can be used for a variety of applications including: Shielding for wires and contacts, End caps to prevent damage to parts in transit, handle grips, Shifter or joystick boots, and so much more.

We stand by our history, and strive to stay a leader in our industry as we have done for the past 50 years. We make sure all of our processes are innovative and effective; we analyze our processes using statistical data to guarantee consistently high quality products. Our trained engineers look forward to helping you from design to development, in order to find a solution to your need. Visit our website or give us a call today for more information on all of Rubber & Plastics Co.’s products and services.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services