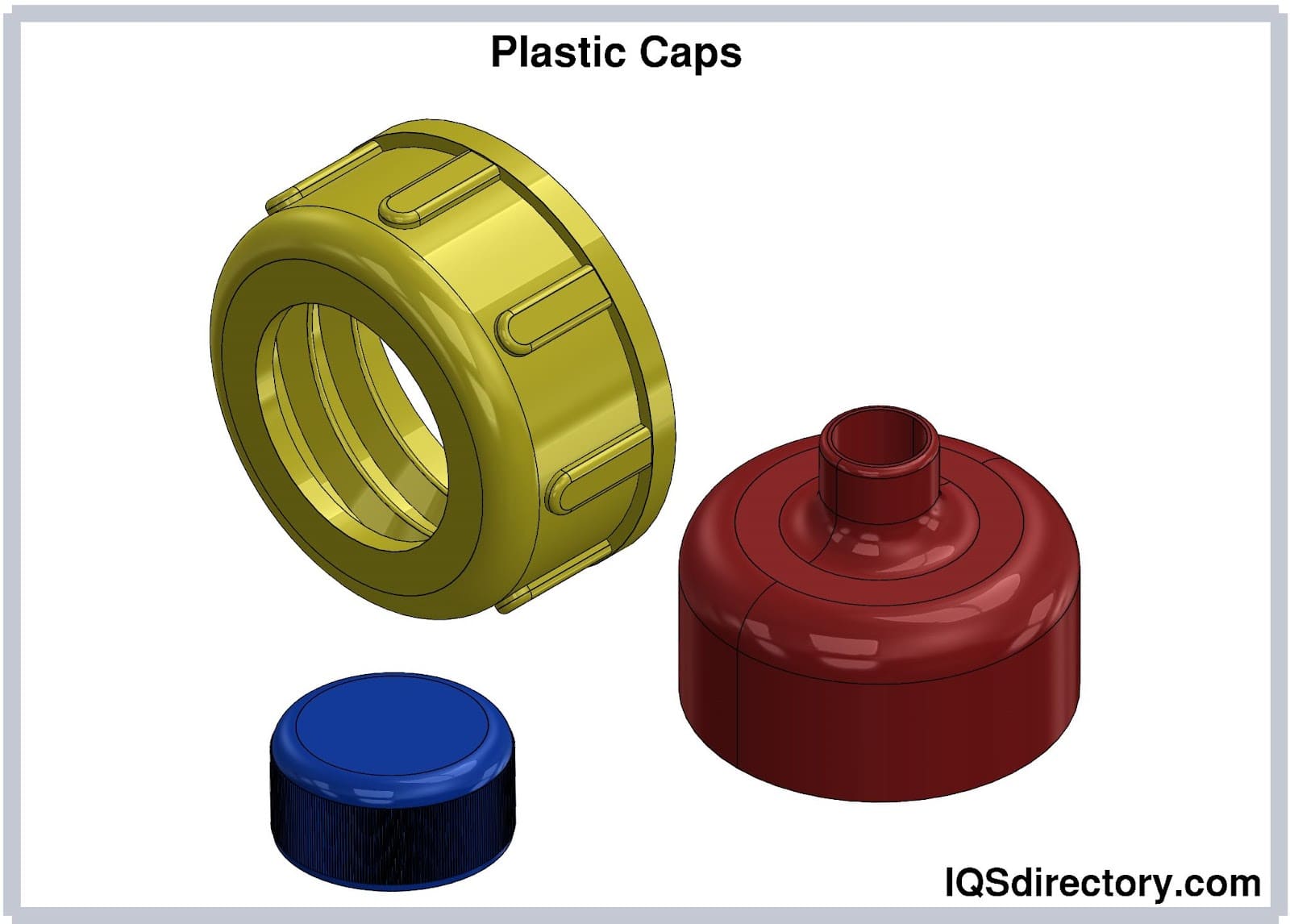

Plastic caps seal the holes, tops, and ends of tubes and containers. Because there are so many different types of containers, tubes, and cylinders, caps are used to cover the openings. They come in various sizes, hues, and forms to suit any need, including bespoke designs. The applications for caps are countless. With particular ones allowed for use in food processing, they can be found in industrial, commercial, and household products. Read More…

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

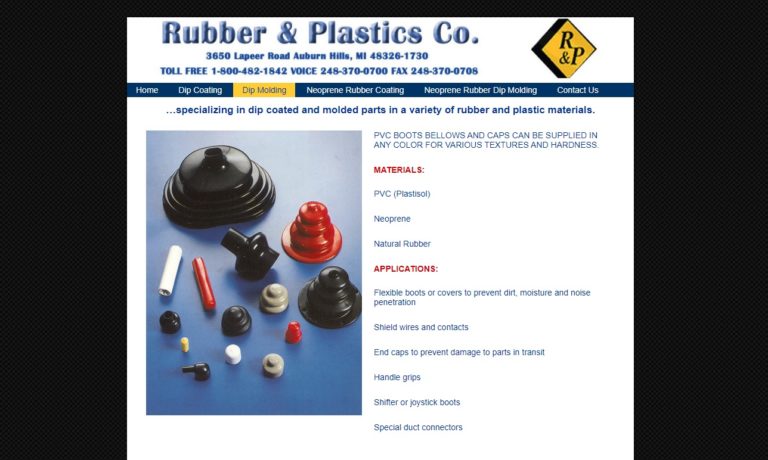

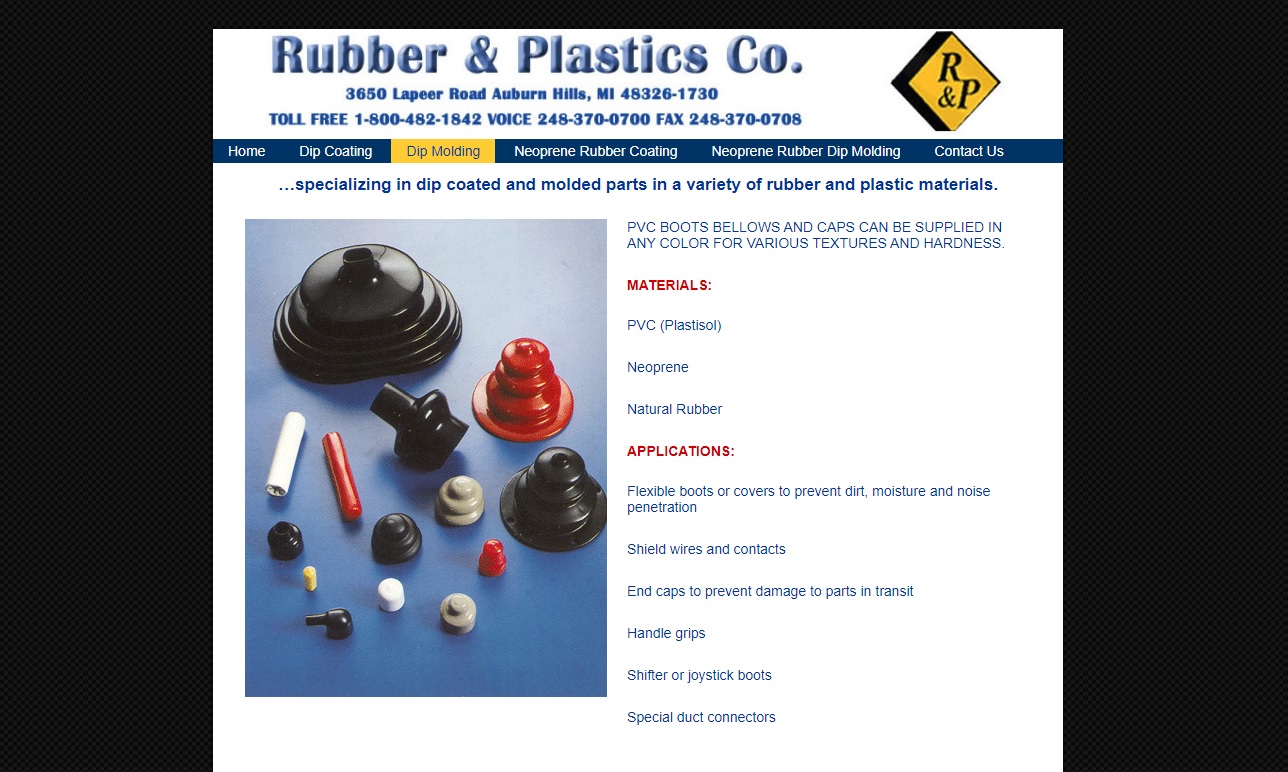

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic Cap Companies

Most plastic caps are made from four types of polyethylene, which were picked for their toughness and strength. Given that plastics used for plastic containers can be less robust than those used for industrial masks and hydraulic pipelines, the material chosen depends on how a cap will be utilized. Threaded and unthreaded plastic caps are another variety that provides a tight seal and stable connection to a container.

How Plastic Caps Are Made

The majority of plastic caps are produced using an approach called injection molding. The thermoplastic polymer pellets used in this technique are heated in a metal hopper to an extremely soft, flexible state. The softened plastic is then carefully and precisely injected into a highly intricate steel mold. The mold shapes the softened polymer for the bottle caps into the appropriate shape. The mold is opened, and the bottle caps are expelled once the polymer substance has cooled sufficiently to solidify.

The caps will be carefully separated from one another and prepared for further processing if multiple caps are produced from a single mold which is frequently the case. For several reasons, injection molding is the most popular manufacturing process for bottle caps. For big manufacturing runs, for instance, injection molding is quite cost-effective.

Additionally, it has great repeatability, which means there aren’t many fluctuations in size, shape, or surface polish from one cap to the next or even from one batch to the next. When threading is involved, injection-molded parts can also adhere to incredibly tight tolerances, which can be crucial. High degrees of detail are supported by the molds utilized, and adding high-quality embossing is made simple. The molds are often made from reusable stainless steel using a CNC machine in a single production run. Every time a mold is used, several plastic caps can be produced.

More goes into their design than merely the geometry required to produce the bottle cap's final shape. Not only do they need to be firmly fastened together to endure hundreds of pascals of pressure during processing, but they also need to eject the components cleanly after the molding cycling is through, and because of the extremely precise dimensions and nearly flawless surface polish that injection molds must-have, the toolmaker must have a high level of competence.

Types of Plastic Caps

Tamper-Evident Cap

At the bottom of a tamper-evident cap, a small plastic ring can be detached from the bottom by turning or twisting the cap. They are created using the same method as regular caps. In addition, a shrink sleeve machine is used to attach them to a container. A tamper-evident band is a piece of plastic that remains on a bottle after a tamper-evident cap is removed. In the pharmaceutical sector, tamper-evident caps are crucial for identifying when a bottle's cap has been removed.

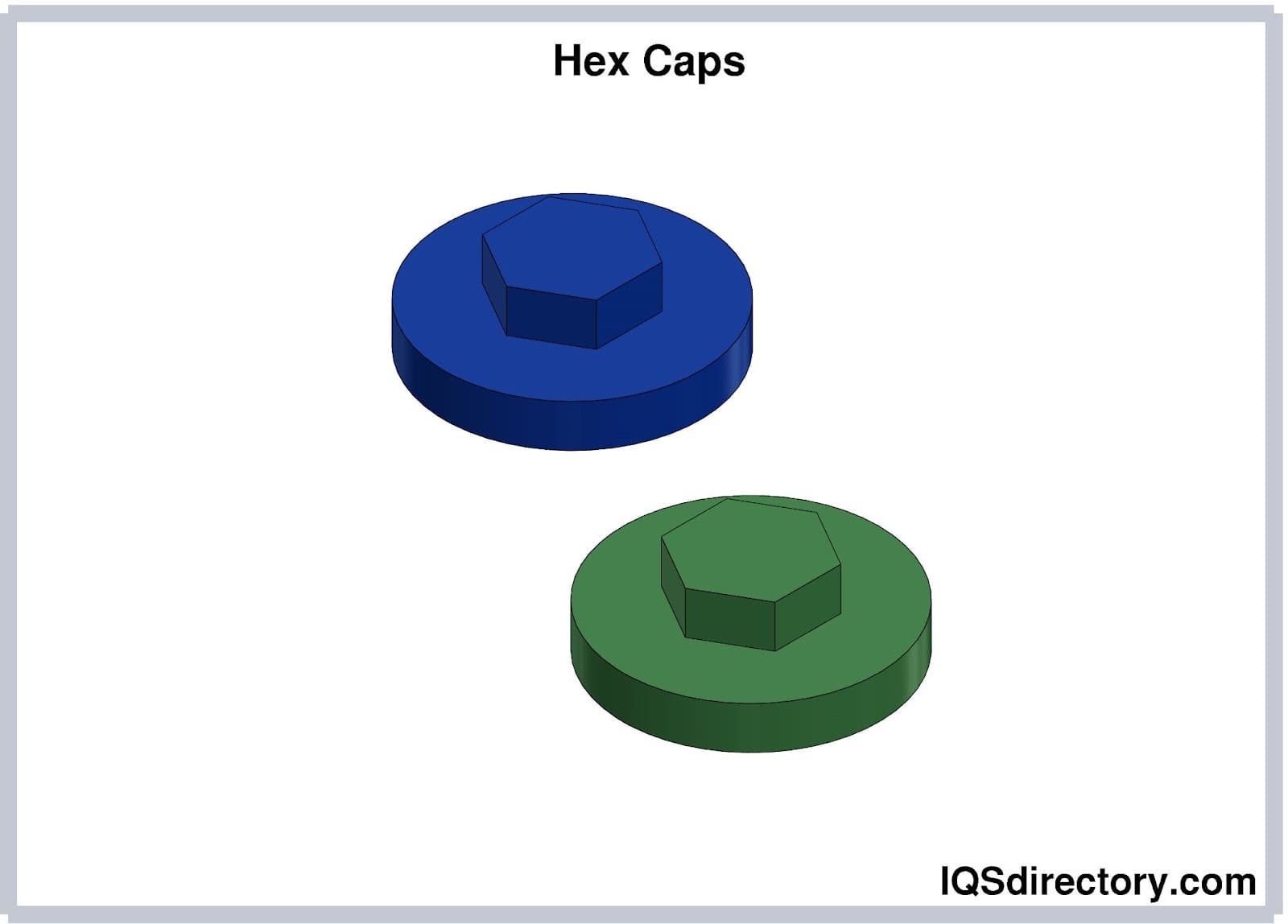

Hex Caps

Hex caps are utilized on protrusions with six sides. They serve as a final touch and a means of protection. Applying hex caps to provide a secure and long-lasting connection is simple. Hex caps stand out among the numerous cap types for their outstanding toughness, longevity, and thick walls.

Utility Caps

Utility caps are made to guard against damage to threaded connectors. They are unthreaded plastic pieces of various sizes that fit securely and tightly over the threads of a sticking pipe. Low-density polyethylene (LDPE) is the material used to make utility caps, which can resist temperatures of -94 °F to 175 °F (-70 °C to 79 °C).

Plastic Threaded Caps

Threaded plastic caps, which can have smooth or ribbed sides, are a closing technique for quickly sealing ends or apertures. They are available in various diameters to suit various application requirements. Threaded plastic caps are practical because they allow a container to be sealed and unsealed several times, keeping the contents safe and undamaged.

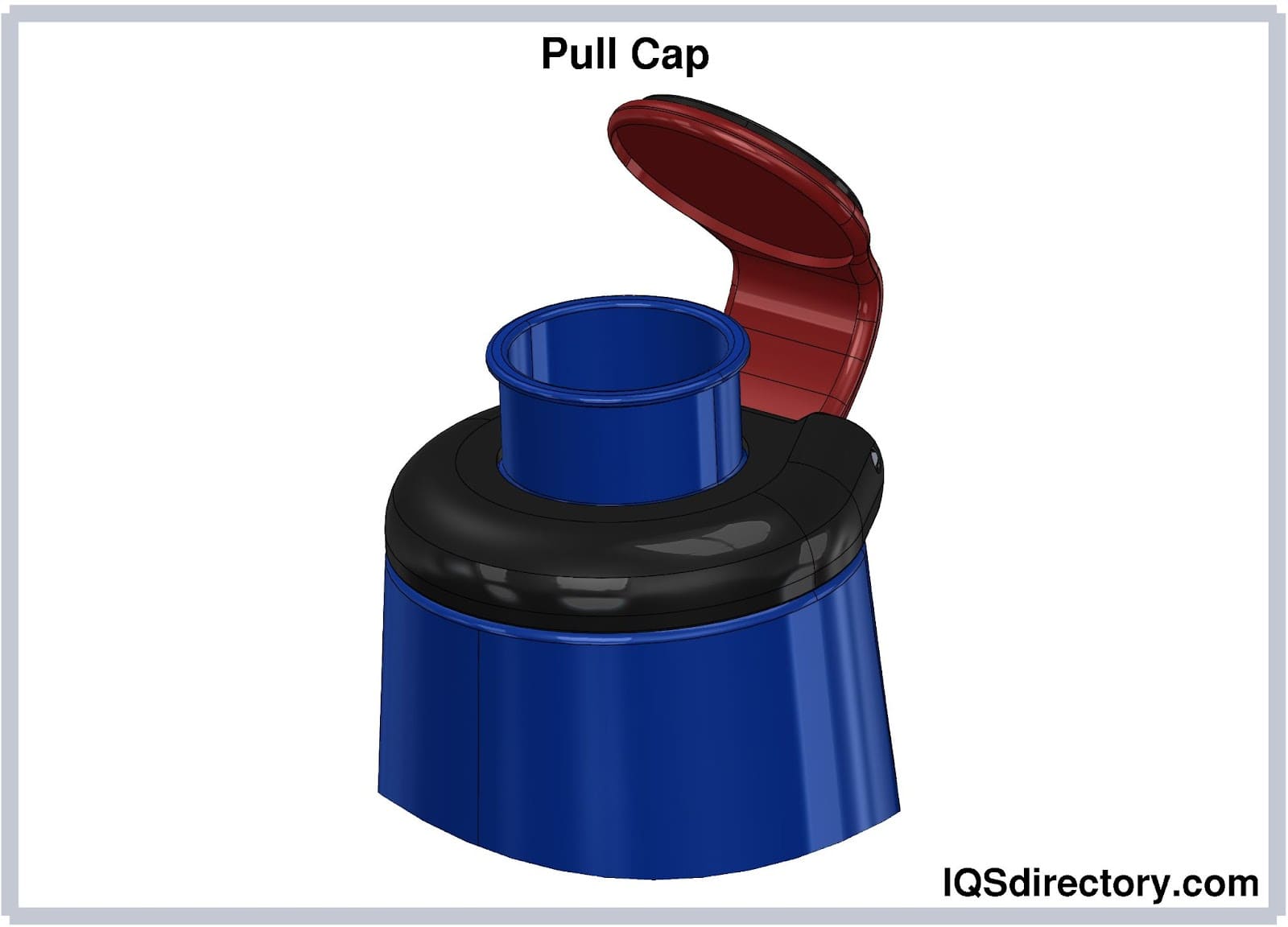

Pull Tab Caps

Pull tab caps include a long tab in the middle of the top, making it simple and quick to remove the cap with a finger. They do not require a tool when removing a cap from the threads it guards. Pull tab caps are made to safeguard threads during powder coating, painting, and plating processes.

Diesel Fuel Injector Caps

Diesel fuel injector caps are made to keep impurities and moisture out while also safeguarding injectors from damage during shipping. They are a cheap and effective LDPE protective technique.

Choosing the Correct Plastic Cap Manufacturer

To ensure you have the most productive outcome when purchasing plastic caps from a plastic cap manufacturer, it is important to compare several companies using our directory of plastic cap manufacturers. Each plastic cap manufacturer has a business profile page that highlights their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic cap company website using our patented website previewer to get an idea of what each business specializes in. Then, use our simple RFQ form to contact multiple plastic cap companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services