There are several methods for plastic dip coating that include: hot dip coating in a fluidized bed of polymer powder, hot dip coating a product in a vinyl plastisol, and spraying polymer powder on a heated product. The method that is used usually depends on the needs of the product being created or the metal being treated. Read More…

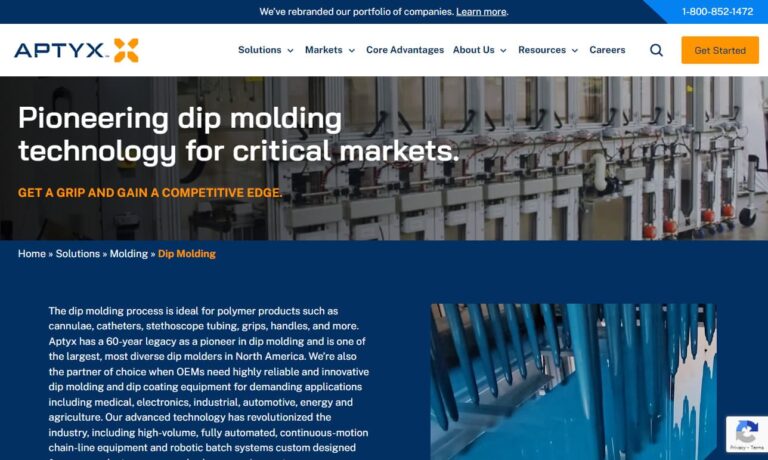

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

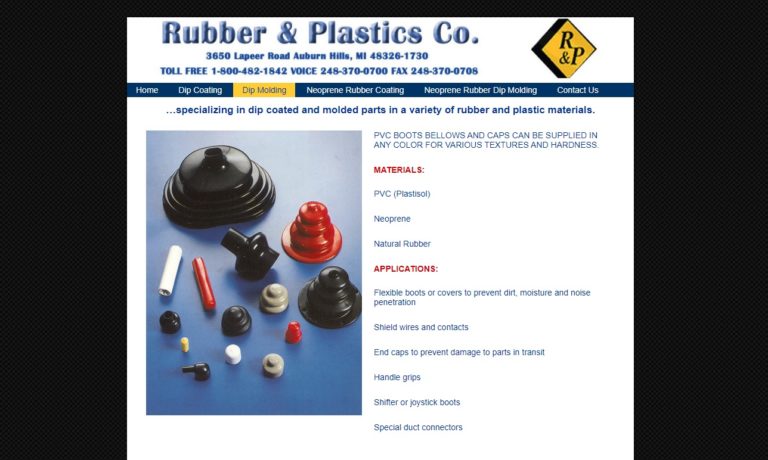

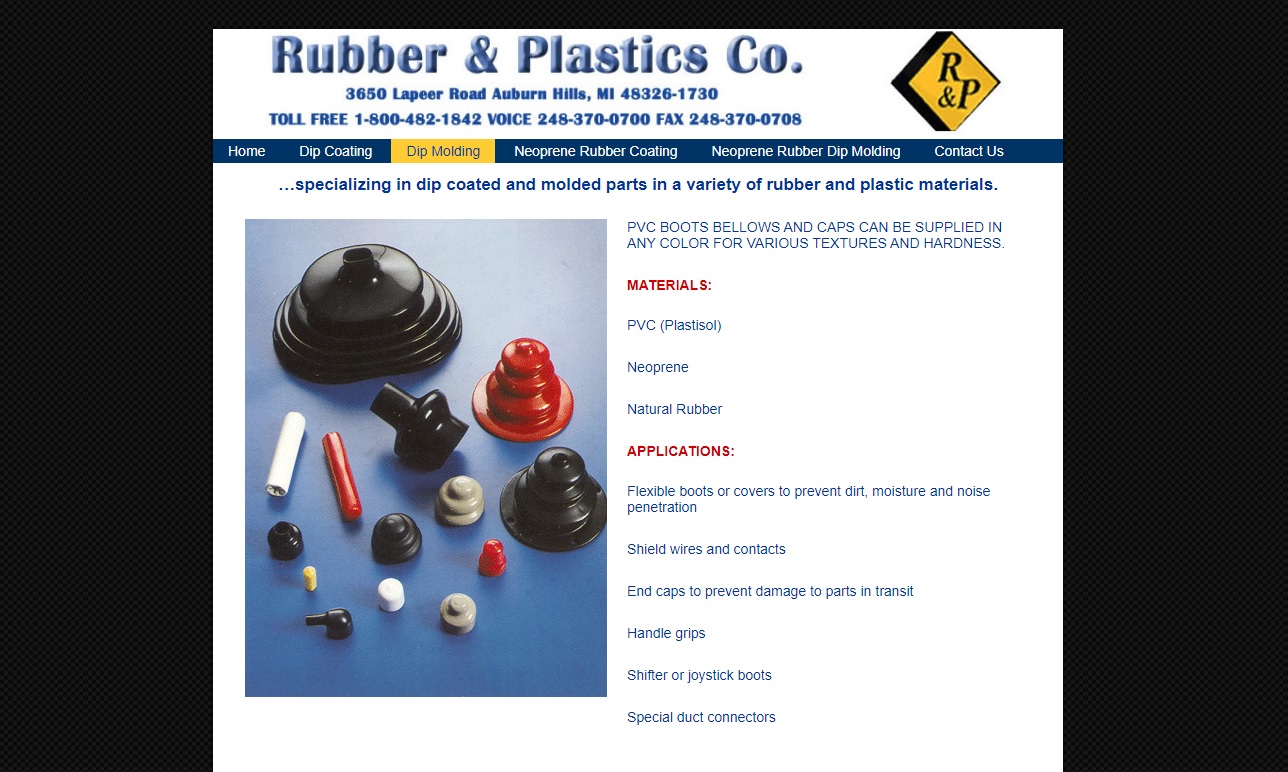

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic Dip Coating Companies

For hot dip coating in a fluidized bed of polymer powder, the metal is thoroughly cleaned and then placed in an oven where it is heated to a high temperature. This heat melts the polymer powder, bonding it to the metal surface when it is dipped in the fluidized bed.

The metal polymer adheres to the surface and the metal is given time to cool, leaving it evenly coated with a smooth plastic finish. Hot dip coating in vinyl plastisol is a very similar process, except the object is dipped in liquid that contains PVC particles.

After drying, the material needs time to cure on the metal to ensure that it adheres properly. The third plastic dip coating method is spraying polymer powder onto a heated product. This is also known as flock spraying. Since some objects are just too large to be coated by dipping them, a spray is used because it is more practical. The part is still heated so that the spray melts and adheres to it on contact.

The product must be reheated if there is any partially melted spray left at the end of the process. The process can be completed several times to add layers of protection to the metal.

Dip coating applications include hand tools, toys, medical instruments, electrical equipment and plumbing fittings. A plastic coating that adheres directly to the metal can significantly improve the lifespan of a product by providing airtight protection from corrosion.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services