Plastic dip coaters use a three step process. First, the product is cleaned and prepared for dipping. Objects are sometimes coated with chromate or phosphate to increase adhesion between the object’s surface and the molten plastic. Read More…

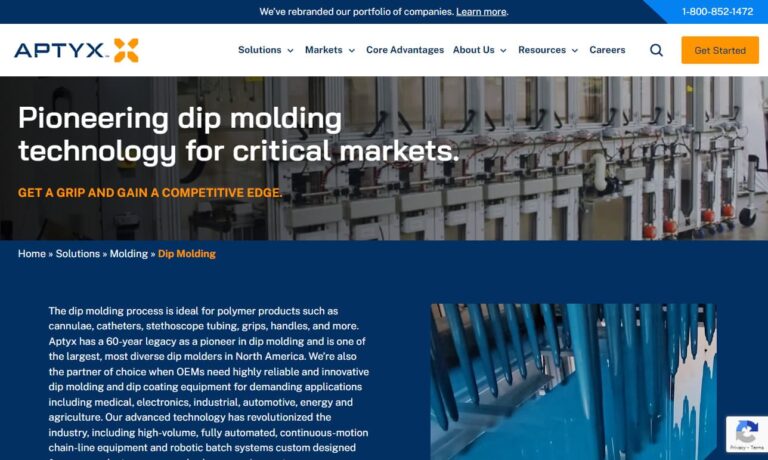

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

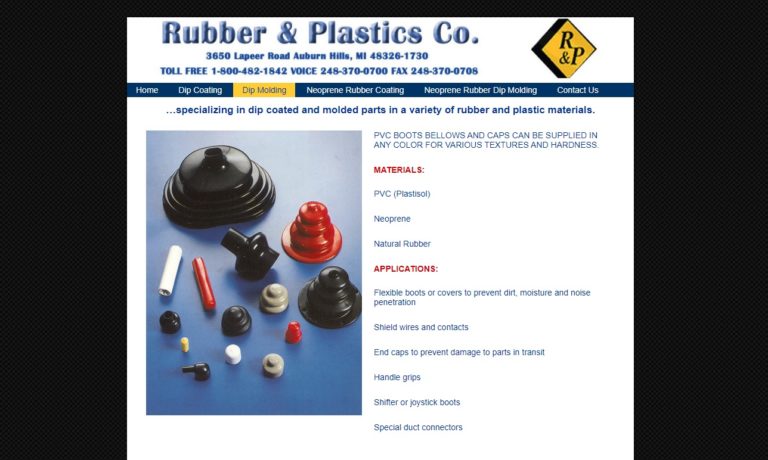

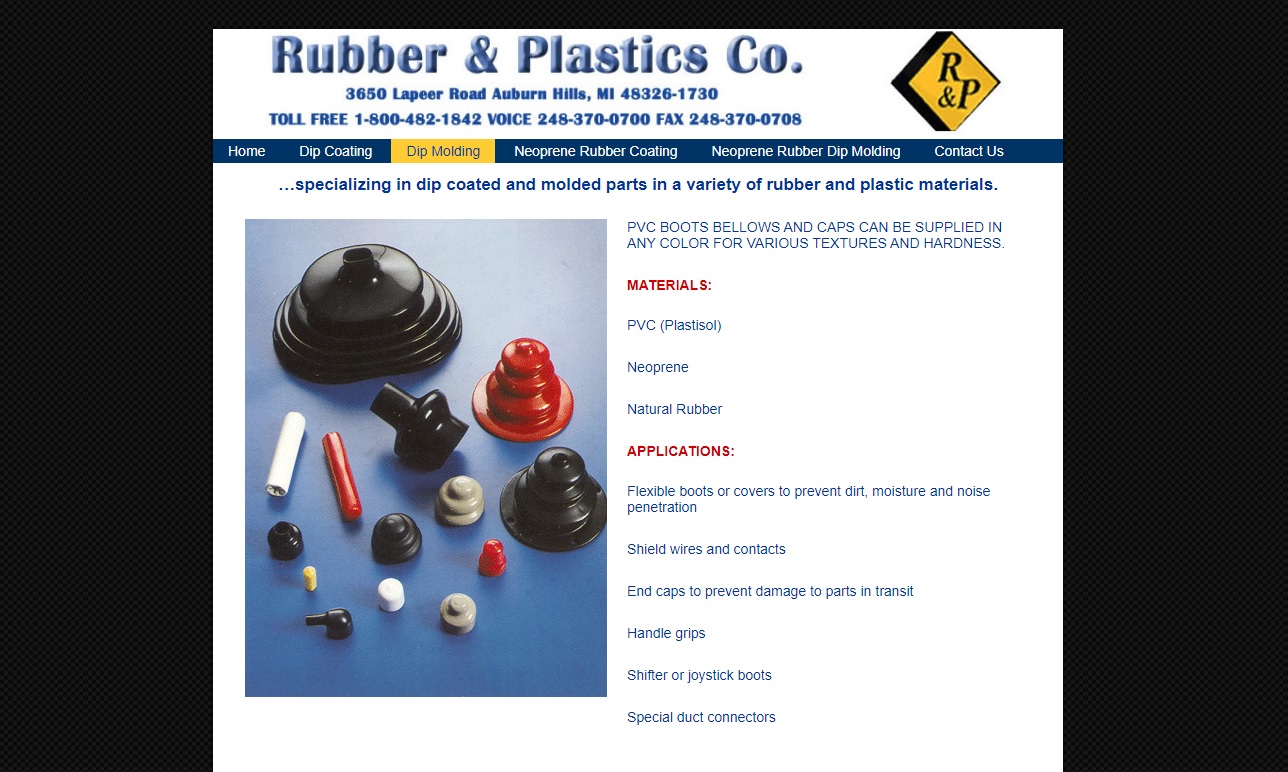

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic Dip Coater Companies

The product is then dipped into the molten plastic and allowed to sit there for a specific time. The longer an object is submerged in the plastic, the thicker the coating will be. Lastly, the object is removed slowly from the molten material and allowed to dry.

Removal speed has to be slow and constant to prevent surface irregularities due to different thicknesses. Objects can be dried and hardened in a heat chamber to ensure fusion between the surface and the coating. Every day objects such as tool handles, fitness and sports equipment, and playground equipment have been dip coated in a melted plastic. The most common material choices for plastic coating are PVC (polyvinyl carbonate) and plastisol which is another form of vinyl.

The purpose of using dip coating is both decorative and protective. Plastic can be manufactured in many different colors, and can be finished according to a desired texture making the decorative capabilities of plastic dip coating very broad. Covering the handles of many everyday objects also improves the comfort and grip for those using the items. However, the more important reason for using dip coating is for its protective and insulative properties. Electrical wires and connectors and products such as jumper cables and plastic closures are covered by dip molding in order to provide thermal and electrical insulation.

Wire fences and other products intended for outside use are plastic coated to protect against corrosion. Further advantages of dip coating include the low labor costs due to the process being almost fully automated. As plastic tends to dry and harden quickly, dip coating can have a high volume turnover in a relatively short time which allows for large batches of products to be dipcoated. Dip coating is not limited by object size or dimension as the container of molten plastic can be adjusted according to dipping needs. For objects such as wire which typically is manufactured in long lengths, a continuous motion dip molding can be used, ensuring total coverage of the surface.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services