Aptyx

AptyxRequest A Quote

Tempe, AZ | 800-852-1472https://aptyx.com/solutions/molding/dip-molding/

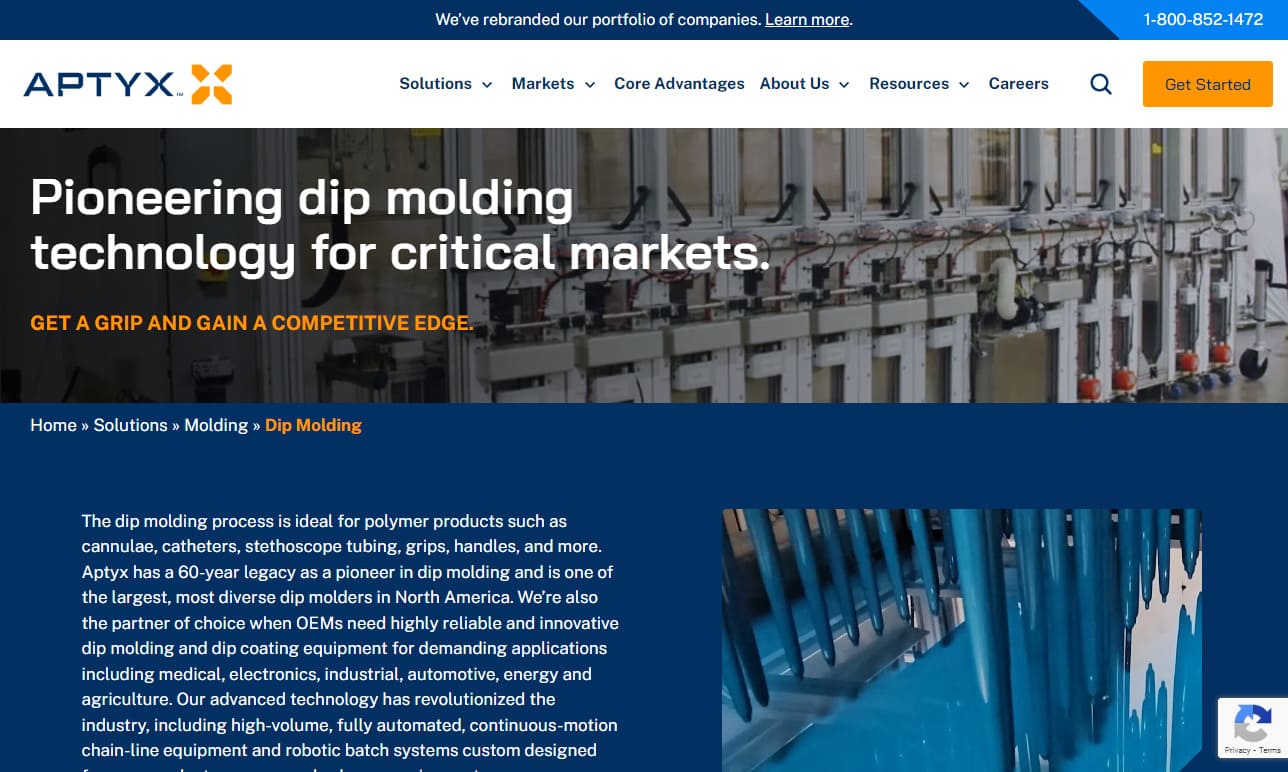

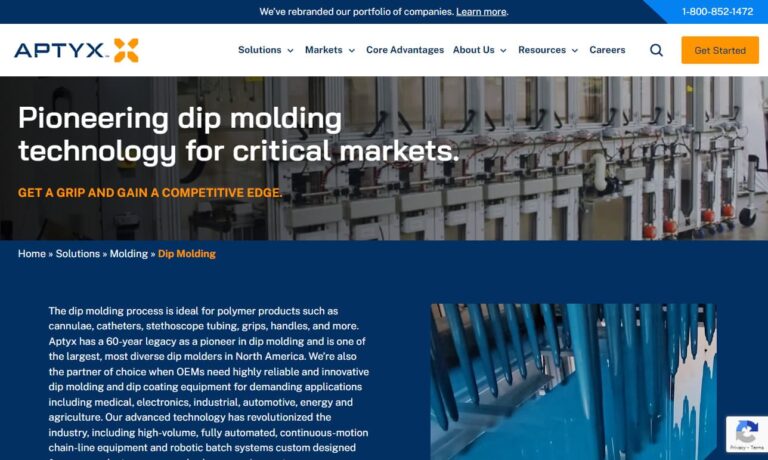

A leader in the plastic processing industry for over 70 years, Aptyx brings together the aptitude and excellence of more than a dozen companies including Molded Devices, US Plastic Coatings, Seitz, Diptech. Across our network of more than ten facilities worldwide, we provide a range of specialized engineering and manufacturing services including injection, blow and dip molding, extrusion, coating and assembly with a focus on delivering high-quality product and exceptional customer service. Our services are vast, including but not limited to design and engineering, prototypes, tooling, electrical resistivity testing, plastic dip coating , hot stamping printing, laser engraving, heat transfer labeling, color matching, silicone pad printing, slush molding, baked-on plastic coating, sand blasting, die punching & metal finishing, and packing. Our plastic processes include plastic and rubber dip molding, dip coating, blow molding, extrusion and rapid prototyping. Within injection molding we are deeply experienced in complex processes such as over molding, two-shot molding and insert molding. Additionally, we offer sonic welding, laser engraving, assembly, warehousing, shipping, and more. We have the precision capability to meet all of your custom tooling needs, and years of experience and confidence in our industry to back up these claims. We have expanded significantly since operations began in 1949. Our large manufacturing footprint is well-suited for high-volume production runs at an attractive cost, but we can handle a range of order sizes from unique, custom work to high-volume. With deep molding expertise, advanced techniques, multiple locations to meet your needs and a customer focused culture, you can count on us. Contact Aptyx to discuss your plastic processing needs!

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services