A coating made of plastic or synthetic resin is a vinyl coating. A metal object is coated with vinyl dip coating to produce a plastic layer that is relatively even and smooth. The thin coating of protective material is placed on the surface of an object, usually to enhance its qualities and to form a barrier against corrosion, abrasion, and wear resistance, as well as surface deterioration brought on by the object’s interaction with its environment. It also gives the object a softer surface and makes it simpler to hold. Additionally, it can give the item unusual hues like black, red, blue, orange, yellow, and green. Read More…

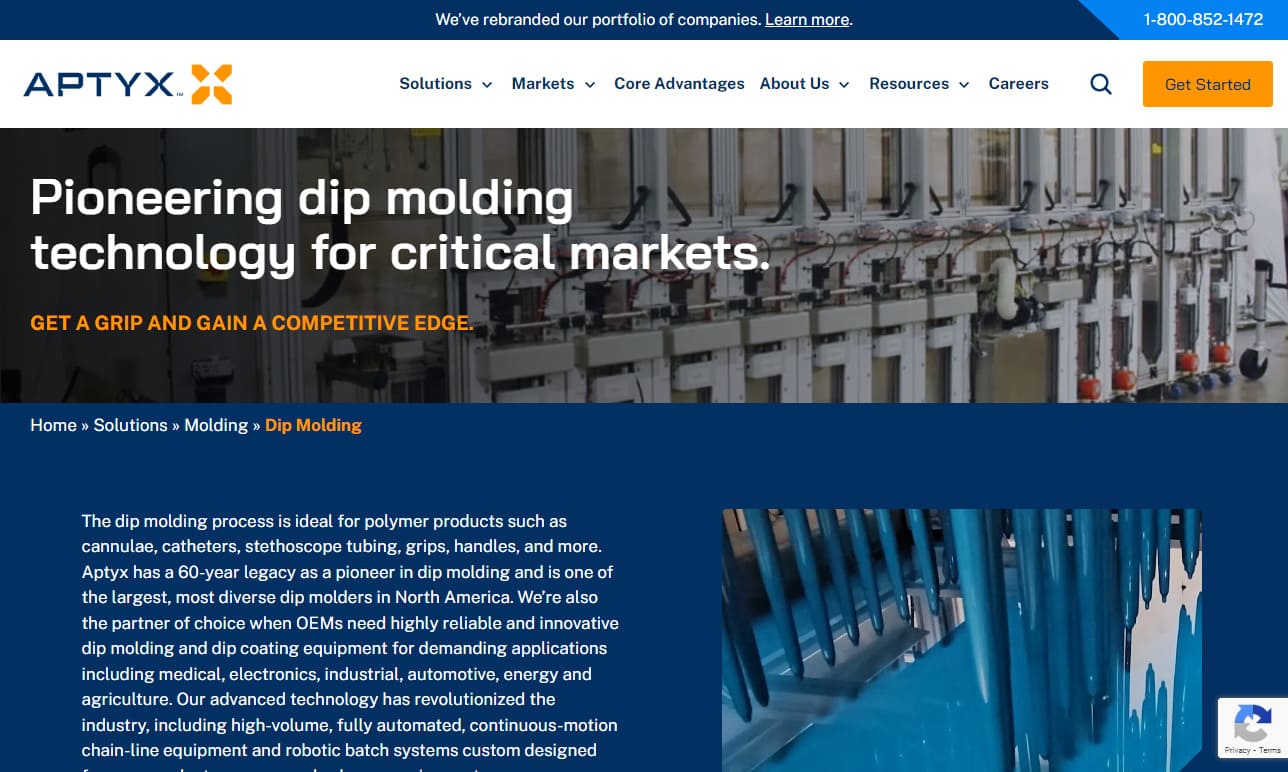

No one has more dip molding expertise than we do! We were a pioneer in dip molding 60 years ago, and we remain an industry leader today. Reach out for a fast, competitive quote on custom dip molding & coating services, from prototypes to low or high volume. We’re your single source for design consult, quick prototyping, custom formulations & secondary operations.

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

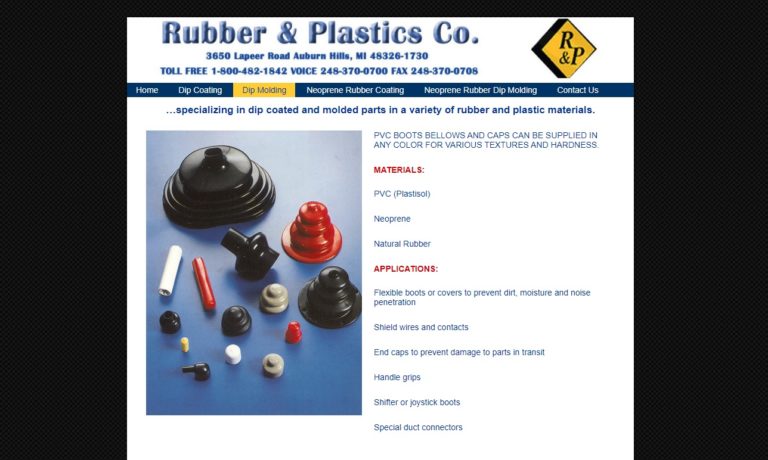

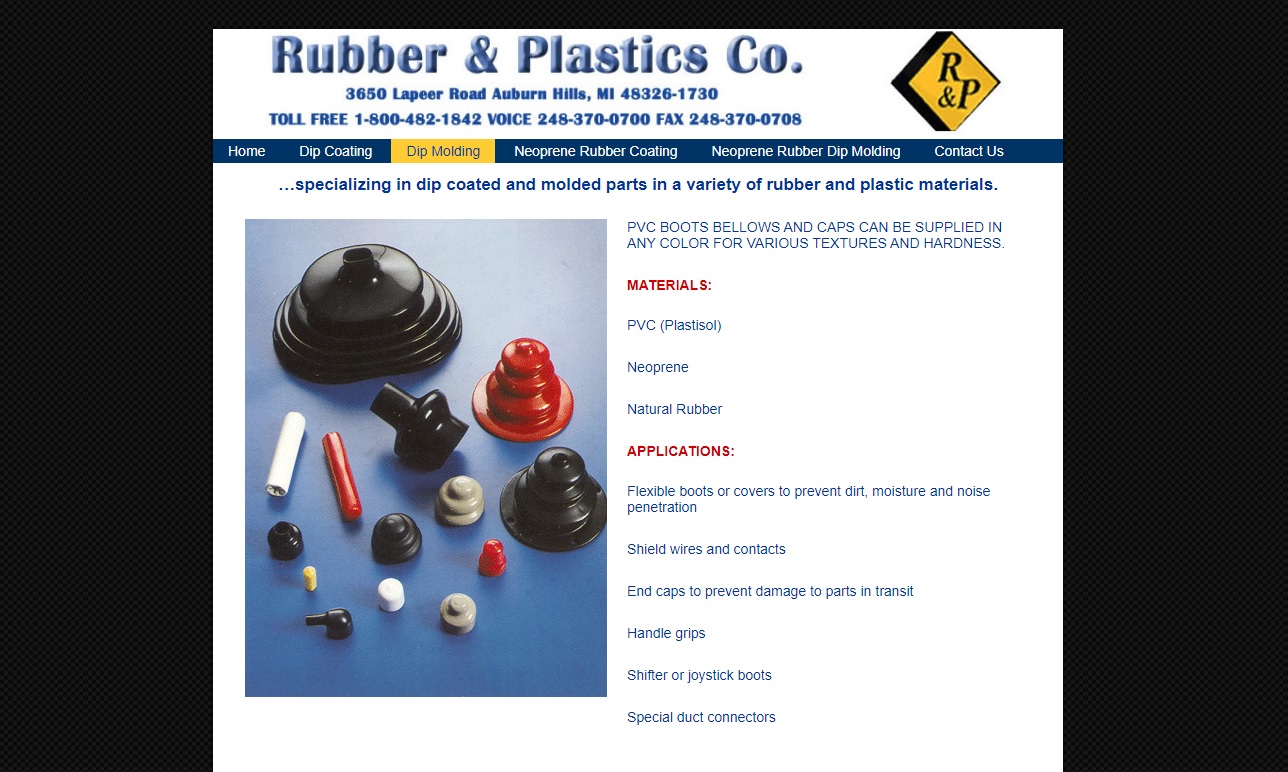

Rubber & Plastics Company has 50 years of experience in manufacturing dip molding with the materials, equipment and flexibility to rapidly prototype. We provide standard and custom designed high-temp paint masks, caps, grips and plugs.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Vinyl Coating Companies

The heated particles produce liquid plastisol, which coats hot objects by dipping them into it. The appropriate thickness, from 1/16" to 1/4", can be obtained using multiple dips. As a result, the metal objects have a soft but durable polish after curing.

In spray coating, it must eliminate substrate flaws, and the substrate must be deburred before spraying. Otherwise, the final output carries these flaws. The liquid vinyl fills in such flaws with precision dip coating to provide a uniform surface. Throughout the three-step dip-coating procedure, a covering of vinyl plastisol develops.

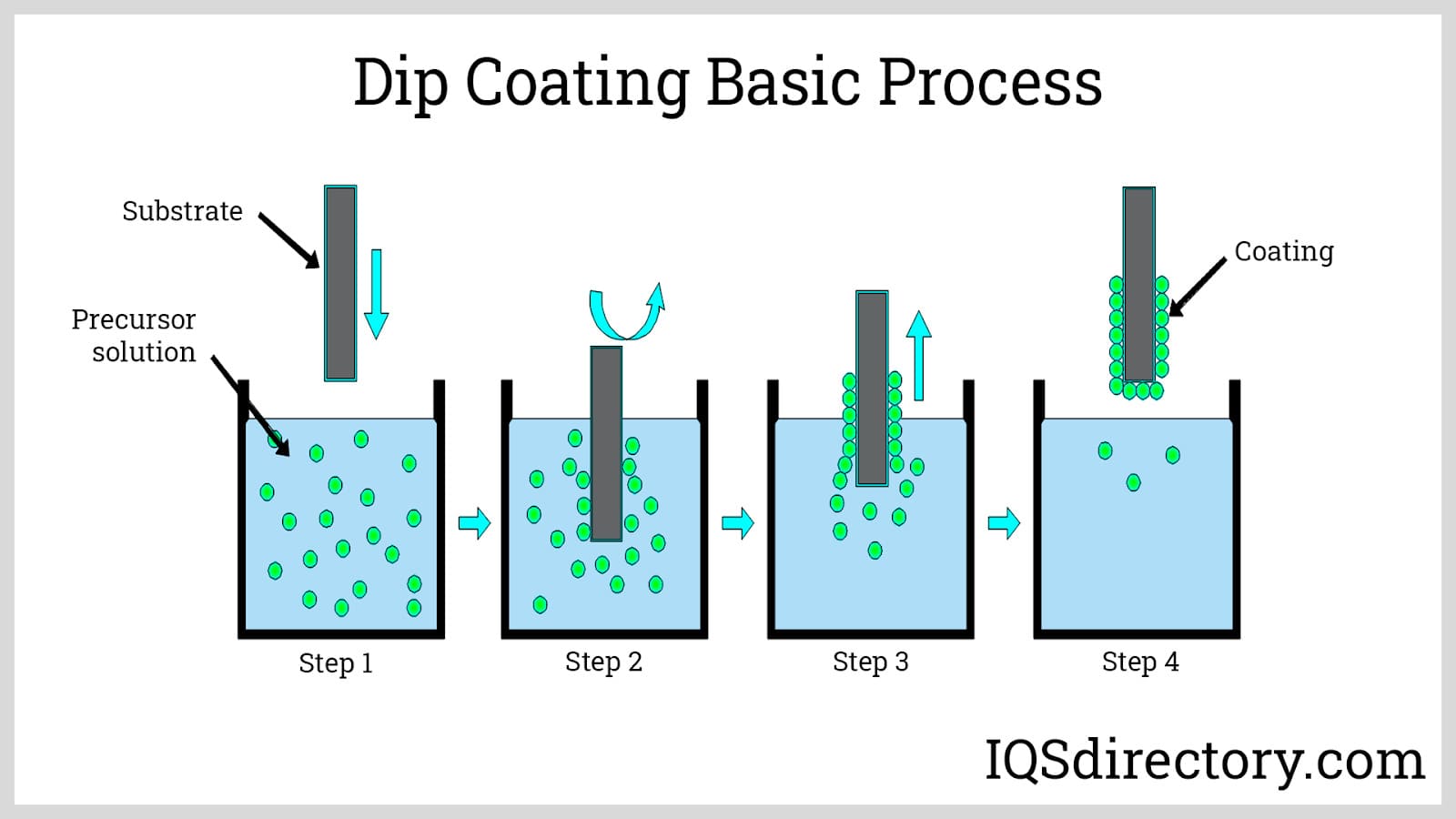

Vinyl Dip Coating Process

Hot dip coating is a typical technique for applying a protective, adornment, or functional vinyl plastisol coating to various metal objects. Products like tool handles and playground equipment fall within the category of typical applications.

Precoating Process

Part Cleaning: Following procedures frequently used to prepare substrates for paint applications, parts to be plastisol coated should be chemically cleaned and phosphate or chromate treated. Substrates can also be vapor-degreased; however, there are better techniques than this. Greater adherence to the primer results from cleaning the substrates of impurities. The corrosion resistance of the metal substrate will also be improved by phosphate or chromate treatments, which will provide adhesion superior to that obtained on metal that has merely been cleaned. Additionally, cleaning the substrate reduces the risk of metal impurities "poisoning" the primer and plastisol liquids.

Part Priming: Vinyl plastisol doesn't adhere to metal very well and needs to be primed if adhesion is required. Primers can be sprayed using standard air spray equipment or dipped into a tank and applied. Primer dip tanks are typically fitted with a pump that redistributes or agitation equipment to reduce pigment separating small particles and sediments in water and stratification by solvent evaporation. Viscosity increases, brought on by the evaporation and adjusted with thinner, should be checked in primer tanks to maintain a constant solids level. In all areas where plastisol adhesion is needed, the prepared metal substrate is covered with primer, flash-dried, and baked until the surface metal temperature reaches between 350°F (177°C) and 400°F (204°C). This procedure prepares the item for the hot dipping procedure and converts the primer polymer system.

Coating Process

Immersion: The substrate is moved steadily and fully or partially submerged in the liquid vinyl tank to accomplish a smooth finish at this stage; it's crucial to maintain consistent speeds and calm, unruffled circumstances.

Dip Time: This relates to how long the coating is in contact with the substrate material. The substrate doesn't move while the liquid is allowed to gel, with plastisol fused to the object. Therefore, it's crucial to keep movement to a minimum during this phase to prevent uneven and erratic coating.

Removal: Removal is the last and, in many ways, the most crucial step. During the withdrawal stage, the object is slowly removed from the coating material and allowed to drain. Time your removal carefully because a thicker covering will develop from removing material more quickly.

Applications of Vinyl Coating

Everything from household improvement products to furniture and military equipment can benefit from hot-dip molding. Here are a few examples of commonplace items benefitting from vinyl dip coatings:

- Any metal exposed to the elements

- Electrical wire insulation

- Military equipment handles and hardware

- Tool handles and grips

- Automotive parts

- Cages for small animals that have surfaces that are resistant to chewing

- Wheelchair rims

- Picnic benches and tables

- Dishwasher racks

- Playground equipment

- Deep fryer baskets

- Outdoor furniture

- Hangers

Advantages of Vinyl Coating

- It's quick, flexible, and environmentally responsible.

- It coats various metal molds and substrates with a strong, long-lasting synthetic rubber covering.

- Due to the dipping technique, it is simple to coat objects of unusual shapes.

- It creates a barrier resistant to wear, corrosion, and abrasion.

- Vinyl plastisol is fire-retardant.

Disadvantages of Vinyl Coating

However, as with any coating, there are some drawbacks to be aware of, including:

- Once it has dried, it is challenging to remove, especially from cracks, corners, and edges.

- It can ruin the paintwork if you remove it after painting it.

- Specialized equipment and tools are needed for the process.

- It is simple to end up with an inconsistent coating thickness.

Selecting the Proper Vinyl Coating Company

To ensure you have the most productive outcome when selecting a vinyl coating company, it is important to compare several companies using our directory of vinyl coating businesses. Each vinyl coating company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the company for more information or request a quote. Review each vinyl coating company website using our patented website previewer to get a better idea of what each business specializes in. Then, use our simple RFQ form to contact multiple vinyl coating companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services